Troubleshooting Common Issues of MC8200 by Janome

Link to Toews MC8200 home page

Troubleshooting Common MC8200 Issues: The MC8200 by Janome is renowned for its precision and versatility, is a favourite among sewing enthusiasts. However, like any sophisticated piece of machinery, it can occasionally encounter issues. Understanding how to troubleshoot these problems can help you maintain the sewing machine’s optimal performance. Here’s a guide to address some common issues you might face with your MC8200.

1. Skipped Stitches:

Problem: One of the most common issues is skipped stitches.

Solution: Start by checking your needle. Is it the right type for your fabric? Is it bent or dull? Replacing a needle can often resolve this issue. Also, ensure that the machine is threaded correctly – both the top thread and the bobbin.

2. Thread Tension Issues:

Problem: Incorrect thread tension can lead to loose stitches or puckering.

Solution: The MC8200 has an excellent semi-automatic tension system so it is rare it needs to be adjusted. If your stitch looks off, start by looking at the needle and threading as described in the above problem. If that doesn’t work, The MC8200 has an adjustable tension system. If you have too much needle thread on the bottom side of the fabric, it will need to be tightened to a higher number (5 and up). If there is too much bobbin thread on the top, it needs to be loosened to a lower number (3 or lower).

3. Fabric Not Feeding Properly:

Problem: If the fabric isn’t moving through the machine smoothly, it can hinder your sewing project.

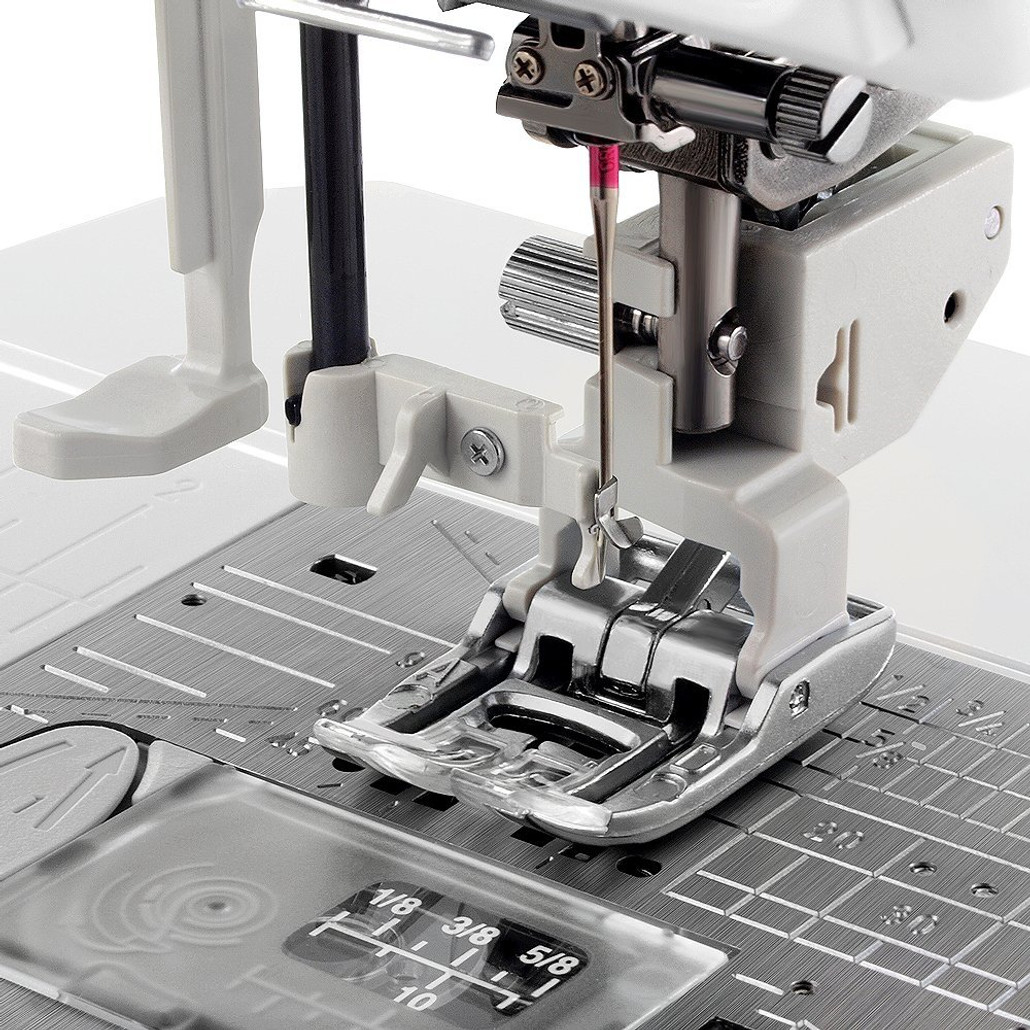

Solution: Check that the feed dog switch is in the up position then press the needle up/down button twice and you should see them come up. Next, look at the where your stitch length is set. It may need to be lengthened. Heavier fabrics require a stitch length of 3 or higher for proper feeding. If it’s a difficult fabric the AcuFeed Flex foot may need to be used.

4. The Machine is Jamming:

Problem: The MC8200 might jam, refusing to sew or getting stuck mid-stitch.

Solution: First, turn off the machine and remove any fabric and thread. Clean out any lint or thread bits from the bobbin area and the feed dogs. A jam can often be caused by small pieces of debris. While you have the needle plate off, inspect the bobbin case for any damage. Rethread the machine carefully, ensuring that both the top thread and bobbin are correctly set. It’s a good idea to change the needle as a dull or incorrect needle can cause jams or they can be damaged during the jam.

5. Issues with the Automatic Thread Cutter:

Problem: Sometimes the automatic thread cutter might not work as expected.

Solution: Ensure that the cutter is clean and free of any thread remnants or lint. If it’s still not functioning, it might need professional servicing.

6. Problems with the LCD Screen:

Problem: The LCD screen may occasionally become unresponsive.

Solution: You may need to do Key Position Calibration, which can be done from the settings menu. For full instructions, consult page 27 in the user manual.

Conclusion:

While the Janome MC8200 is a marvel of sewing technology, understanding its nuances and troubleshooting minor issues can enhance your sewing experience. Regular maintenance, such as cleaning and appropriate settings adjustments, can prevent many common problems. Remember, your sewing machine manual is a valuable resource. And for those issues that defy easy fixes, don’t hesitate to reach out to a professional technician. With a little care and know-how, your MC8200 will continue to be a reliable and efficient partner in all your sewing endeavours.

EXCEPTIONAL CUSTOMER SUPPORT: Janome prides itself on providing excellent customer support,

Additionally, the machine comes with a 25-year limited warranty, ensuring the user’s peace of mind.